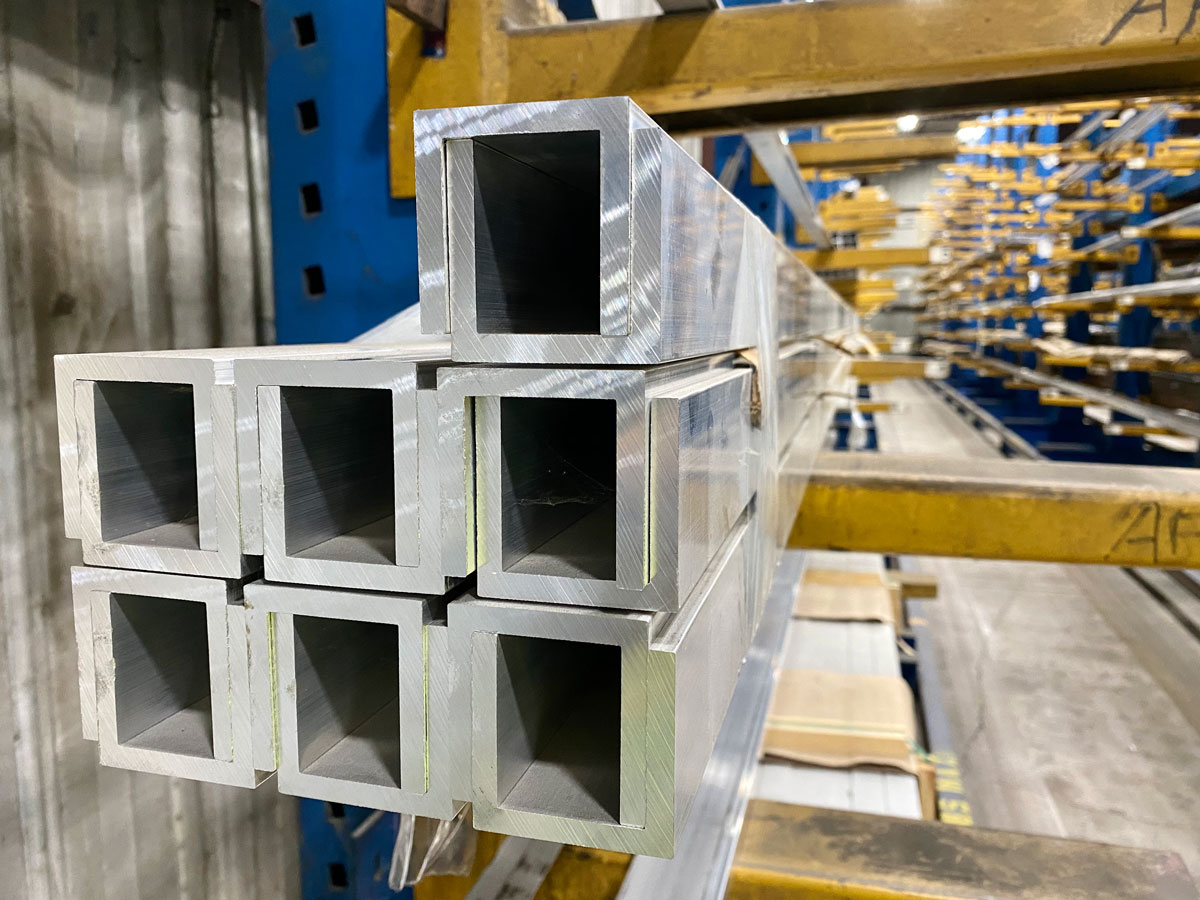

Extrusions

Aluminum

The aluminum extrusion process involves pushing a heated aluminum billet through a die, via hydraulic press, in the shape of the finished part. The extrusion is cut or sheared when it reaches the desired length and subsequently cooled and stretched to achieve desired mechanical properties. Extrusions may then be artificially age hardened via a heat-treating process in age ovens, which further enhances the mechanical properties in a controlled temperature environment.

The primary commercial quality alloys used in extruded products are as follows:

6061 This is the workhorse among heat treatable aluminum alloys, for it combines many of the best properties that aluminum alloys are capable of exhibiting in processing and in service. It is age hardened either naturally (-T4) or artificially (-T6) and has excellent corrosion resistance in the hardened tempers. 6061 is very versatile and can be used in sheet, plate, and extruded products.

6063 This alloy is available in extruded products only. The optimum combination of tensile properties and fine-grain structure that permits light cold forming is achieved by the extrusion of shapes in a critically narrow temperature range with subsequent age hardening. It can be welded and brazed. Its excellent corrosion resistance accounts for its routine application in exterior architectural applications. It machines at slightly higher speeds than 6061.

Reliance Metalcenter offers a wide variety of aluminum alloys and tempers for commercial applications.